A rod tail is a cylindrical extension on the end of a clock hand, used to counterbalance the clock hand. Typically it extends from the center of the hand to the end or tail. In many cases it’s finished to match the color of the clock dial that it is mounted over, alternatively, it’s the same color as the body of the clock hand. In some special cases, it has a special finish, such as polished brass. Clock hands are balanced to alleviate excessive wear on the tower clock movement.

Clock hands can also be balanced using hidden counterweights on the tails of the clock hands. The object of balanced clock hands is for the center-to-tip portion of the clock hand to weigh the same amount as the center-to-tail portion, thus being perfectly balanced at the point where they are attached to the clock movement.

Please contact us via phone 508.359.4396, email salese@electrictime.com, our info request form, or the request info form tab on the product you are interested in pricing. We will get right back to you with prices and/or a price list.

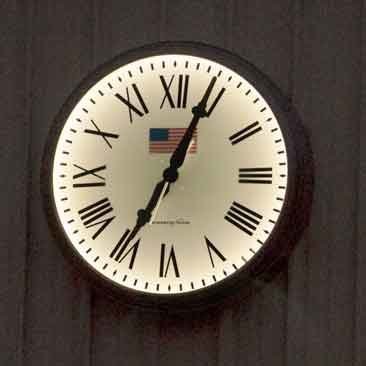

An Executive Clock is a name given to a silhouette clock or gallery clock, typically installed in a boardroom or an executive office. Typically our Style 1000 or Style 1100 tower clocks, or our 40900 gallery clocks can be used in this application. The term is used to denote a formal, often interior, setting for the clock.

Look no further than Electric Time Company. We carry a wide selection of parts, including motor replacements for type B3, C5, and C5M rotors used on B28, C1, #4, #5, and #7 tower clock movements, to keep your clock running smoothly.

For more information or to request specific parts, please fill out our service form and attach photos of your clock to help us better understand your needs. Our team of experts will be in touch with you shortly to provide further assistance

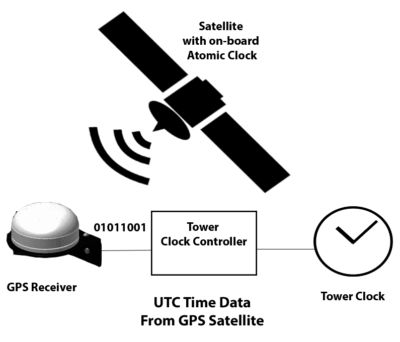

The GPS satellite system consists of 32 satellites orbiting the earth. Each satellite has an atomic clock synchronized to UTC time and broadcasts this information – along with the position of satellite – on a radio signal. Our GPS Receiver converts this information into a serial data stream and sends it to our tower clock controller, which computes the offsets for your local time zone and corrects for daylight saving time if required.

The GPS satellite system consists of 32 satellites orbiting the earth. Each satellite has an atomic clock synchronized to UTC time and broadcasts this information – along with the position of satellite – on a radio signal. Our GPS Receiver converts this information into a serial data stream and sends it to our tower clock controller, which computes the offsets for your local time zone and corrects for daylight saving time if required.

Our GPS Receiver has to be located so it has a “RF transparent” view of the sky, so it can be mounted outdoors, or inside of “RF transparent” materials such as wood or plastic.

Note: “UTC” time is Coordinated Universal Time, or essentially Greenwich Mean Time (GMT).

The rule of thumb for the size of a tower clock is a 1 to 10 ratio. However, this is only a rule of thumb – sometimes tall towers have smaller clocks, or large clocks are placed at the entrance of buildings. Buildings that have long horizontal dimensions also typically require a larger clock than the rule of thumb.

We are happy to make recommendations. Please email us an elevation or photograph.

Explore our full range of tower clocks, complete with Architectural Specifications and CAD Details, by clicking here.

Our standard painted finishes are: blue, medium or dark bronze (matches Duranodic #312 & #313), off-white, matte-black, satin aluminum, forest green, red, bright white or gold.

Our painted finish system consists of an acid etch primer, catalyzed polyurethane painted finish and protective clear coat. We have had our painted finishes tested by the leader in paint testing – Q-lab – with accelerated weathering, light stability and corrosion testing.

Special finishes are also available: Custom color matches, Verde Green, Copper Patina, Gold Leaf and brushed, circle-line or polished finishes over the base material. If you have a special finish not listed here, please contact the factory.

Click here to download our color chart: DS-467

Please note that printers and monitors may distort the colors.

We find acrylic scratches easily and polycarbonate will yellow with time. A tower clock or street clock is meant to be a center of attention for decades if not centuries. Glass does not deteriorate with time. Tempered glass is relatively strong and will only break if hit with a sharp object. It then breaks into small pieces. This is the same material used in the side window in cars. If not properly installed acrylic and polycarbonate will warp. If required in areas prone to vandalism polycarbonate and/or special acrylics crystals are available.

Left – aged crystal removed during clock renovation. Right – warped & scratched crystal.

Yes our tower, street clocks and automatic controls are listed in their entirety under various UL standards. Members of our engineering staff serve on a UL standards committee.

No. Manufacturers often claim that products containing UL recognized components and UL listed parts have been properly certified as safe. This is not the case, in order for a product to be “UL Listed” it needs to be evaluated in the entirety under the applicable UL standard. Electric Time Tower & Street clocks and controls are listed under UL standards applicable to the specific product.

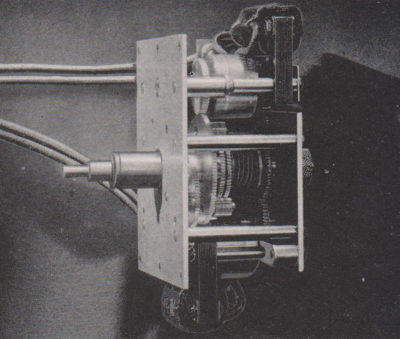

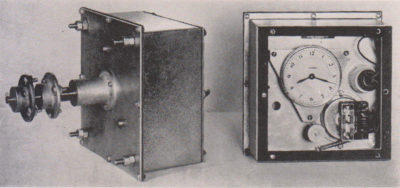

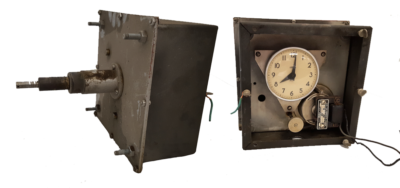

We still carry parts for 95% of the products we have made since 1928. Unique in the industry we are the only street clock manufacturer that makes it’s own clock movements and controls. We can fix clock movements made 90 years ago. No other firm can offer this. Photographs below are of a clock installed in 1941, it has the same clock movement for over 75 years.

Without GPS: Yearly, when control located indoors +- 1 minute, outdoors +- 3 minutes. With GPS: 1 microsecond 1×10-6.

Standard size clock movements and controls are stock items, other products are made to your specification in our manufacturing facility in Medfield, Massachusetts USA. Lead times vary based on the product and scope of design. We will work with you to meet your requirements and will make delivery dates required for your deadline.

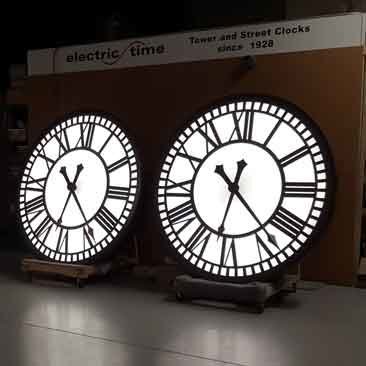

We use a variety of different methods to light both our tower and street clocks with LEDs. Our standards include backlighting, and edge lighting, we also can provide halo and surface mount lighting on clock hands and dial markings (see products & specs – 1000/1100 Silhouette – Illuminated ). Our backlighting is even, with light sources spaced back from the clock face to eliminate hot spots. Various options are available, ranging from dimmers, RGB (color changing), and warmer and cooler whites, contact us for details.

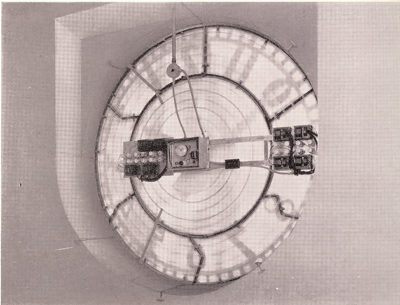

Our tower clock movements are “Pulse” driven – they run 6 seconds of every minute. The motion is smooth, not jerky, and used on clocks up to 35 ft. in diameter. This tower clock movement design is backwards compatible both electrically and physically with tower clock movements we have been making for the last 70+ years. Synchronous movements are also still available from our firm.

As required per UL 48 & UL 863 specifications we provide drain holes in our products.

All of our clock products use split hand hubs to attach the clock hands to the shafts. We do not use set screws as they will loosen with time. This prevents the hands from becoming loose in strong winds and/or adverse weather.

Animated Hub Image

The Howard and Seth Thomas Street Clocks have a controller mounted in the base. This control will automatically reset for Daylight Saving Time changes and power failures and kept accurate with a GPS receiver. It is listed under UL standard 863. It is not necessary to have a large industrial exterior cabinet to house the control.

There does not seemed to be a definitive reason why the number four is represented by IIII rather than IV, but it is how the dials on tower clocks have been done for centuries.

Possible reasons include:

- IV was commonly used to notate the Roman god Jupiter (in Latin, Ivpiter), and the numeral IIII was used to differentiate

- Visually, IIII forms better symmetry with the VIII on the other side of the clock; as well as creating radial symmetry in that only I appears in the first four hours, V only appears in the second four hours, and X only appears in the last four hours

- IV is oddly positioned and difficult to read from the normal angle where four appears

- Romans simply preferred IIII as they largely avoided subtraction

For further commentary, please see this document by Don Lathrop, or Wikipedia.

This is a traditional process; the background of the dial is finished with a “black smalt”. Specifically, ground black glass is attached to the clock dial with a binder. If the dial markings and hands are finished with gold leaf, the contrast with the black can be very striking.

Photograph below of a black smalt Style 1100 design Tower Clock.

Our aluminum castings are made here in the New England area at local foundries. The foundries use our wooden patterns to make the castings. Pictured below is the progression of the process. At far left is our original Howard Company wooden pattern used exclusively for the post in Electric Time Company’s Large Howard Replica Post Clocks. The photo second from left shows the post as it arrives in our factory from the foundry. After going through a number of processes in the factory the finished results are shown on the two photos at right.

The casting process starts with the wooden molds which are pressed into wet sand that will hold the mold’s shape. The molten aluminum is poured into the mold – which is also modified using a core box for the inner shape of the cast piece. These cast pieces are manufactured to our strict specifications for purity, thickness and strength.

Electric Time Company uses aluminum rather than fiberglass for its street clocks. Aluminum provides a stronger, sturdier clock – not likely to need any repairs or upkeep. Fiberglass is a less expensive medium, but not one we prefer for our post clocks.

Casting process: (left to right) original pattern – casting – finished results